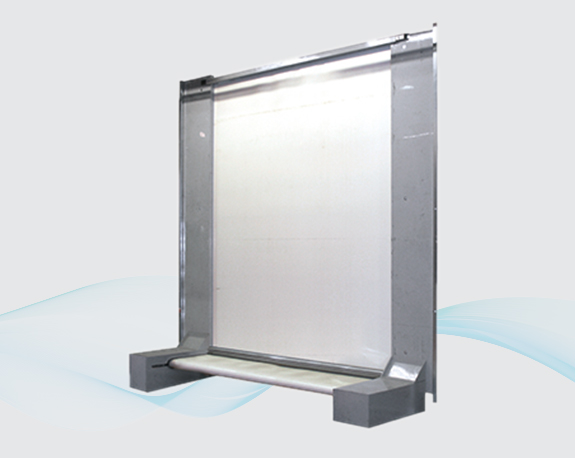

It consists of a sliding belt, entirely made of sturdy non-stick material which is interposed between the part to be painted and the suction booth.

It allows the recovery of about 90% of the overspray, i.e. paint that is normally wasted because it does not adhere to the painted part.

The belt is maintained constantly humidified by adjustable nozzles, so as to always maintain the correct viscosity of the paint.

The paint that adheres to the wall can easily be collected with a blade located on the back side of the machine; once it is filtered and mixed with new paint, the paint can be fully reused, keeping the same chemical characteristics of the initial product.

The machine automatically cleans the floor at the end of the cycle, allowing fast color changes. This allows a 45% reduction of the cost of paint and 90% of the cost of the booth filters. The wall can come with integrated suction, also sliding on guides, so as to move away from the operator and allow the rotation of the piece holder bar, where an automatic painting plant is being used. This is compatible only with single-component water-based paints.