Modern dust collection systems are much more complicated than when they were first introduced nearly 100 years ago. Much of the current dust collection technology has been around for decades, yet recent advances in safety features and digital components have moved the whole industry forward in terms of efficiency, environmental impact, and disaster prevention & mitigation.

It’s that last concept that we will cover in greater detail in this article: disaster prevention & mitigation.

The National Fire Protection Association (NFPA) has provided codes and standards for use by local governments for over 120 years, and more recently has provided detailed standards regarding industrial processes including dust collection and storage. This recent attention to industrial processes is not based solely on good practice, but is inspired by past experience with industrial accidents and disasters. All too often these preventable chains of events result in death or dismemberment of workers at the facilities which suffer from inadequate procedures. Properly installed and maintained explosion prevention systems can save lives, spare devastating damage to facilities, and minimize process downtime in case a potentially hazardous event should occur.

There are a number of NFPA codes which cover the detection and prevention of catastrophic deflagrations: NFPA 69, NFPA 650, NFPA 652, NFPA 654 and NFPA 664. Spark detection (also called optical detection) is an important part of all of these standards. However, these devices are just one part of a larger system of devices and processes, including regular maintenance and good housekeeping.

When an explosive event occurs within a facility which produces combustible dust the risk for fire propagation is extremely high. The shockwave from the initial event can cause more dust in the immediate area to become airborne ahead of the flame front, which travels slower than the pressure wave. This causes more dust to become airborne ahead of the flame front, providing more fuel and a secondary, often larger, explosion. As long as there is fuel for the fire it will spread, and if the space is confined it becomes disastrous and destructive. With proper safety equipment, disaster can be avoided and lives saved. Spark detectors are a crucial component of these safety systems.

HOW A SPARK DETECTOR WORKS

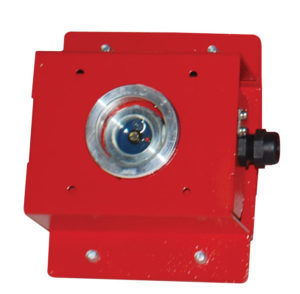

A spark detector is a simple device which monitors the infrared light within the field of view of a special sensor which detects light in the infrared range. This light is emitted from all things which emanate heat, and sparks or burning embers emit a greater amount of infrared light in contrast to the surrounding area within a typical room, workshop or factory floor. Fire is also detectable by the spark detector, which means any deflagration event within the ductwork will be registered and abated by a properly designed fire extinguishment system.

Infrared vs. Visible Light (Credit: NASA.gov)

What makes a spark detector different than a standard infrared camera or other sensor is how quickly it operates. For a spark detector to be effective it must sense a rapid change in infrared light coming from a tiny hot particle traveling at high speed through its field of view. Once a spark has been detected, a signal must then be passed to the fire protection system. That system will then process the signal and mark it as an emergency event, which will then initiate fire prevention mechanisms associated with a spark being detected at that location in the dust collection system.

EcoMAXX Spark Detector, by BOSS Products America

All fire prevention devices must be activated before the spark reaches their locations within the collection system in order to be work as intended. To give you an idea of how fast these systems must operate, a particle flow of 4,000 FPM is about 45 mph and 5000 FPM is almost 55 mph. The spark detection & extinguishment cycle must be almost instantaneous in order to prevent disaster, because it only takes one spark to set off an explosion.

WHAT SPARK DETECTORS CAN DO

Spark Detectors are the primary sensor in an explosion prevention package used with a dust collection system. They can be tied to activate a single safety component or multiple devices connected to the Fire Control Panel, a programmable logic controller which determines what happens when certain input signals have been received.

There are specific requirements for detector & device placement:

- The ducting MUST be straight and uniform throughout the length for even airflow and constant velocity; no elbows, transitions or branches can be positioned along this path.

- The spark detectors MUST be installed 1.5 times the diameter of the ductwork downstream from any elbows, transitions, branches or any other fittings which could affect the laminar flow of the air stream.

- The device being activated by the spark detectors has its own rules for placement in regards to fittings and distance to the dust collector or other equipment; the placement of these devices determines the upstream placement of the spark detectors along the ductwork.

SPARK EXTINGUISHMENT

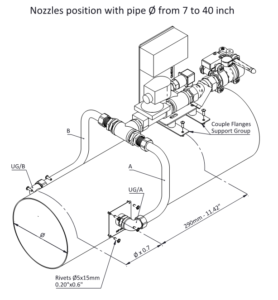

Spark detectors can be paired with a Spark Extinguishment Set, which are a set of nozzles mounted to the ductwork that pop into the air stream and spray water to quench a flame, similar to automatic fire sprinklers in a building. These are placed at an appropriate distance downstream from the spark detectors so that the spark travels through the water spray and is extinguished before it reaches the dust collector.

EcoMAXX Spark Extinguishment Set, by BOSS Products America

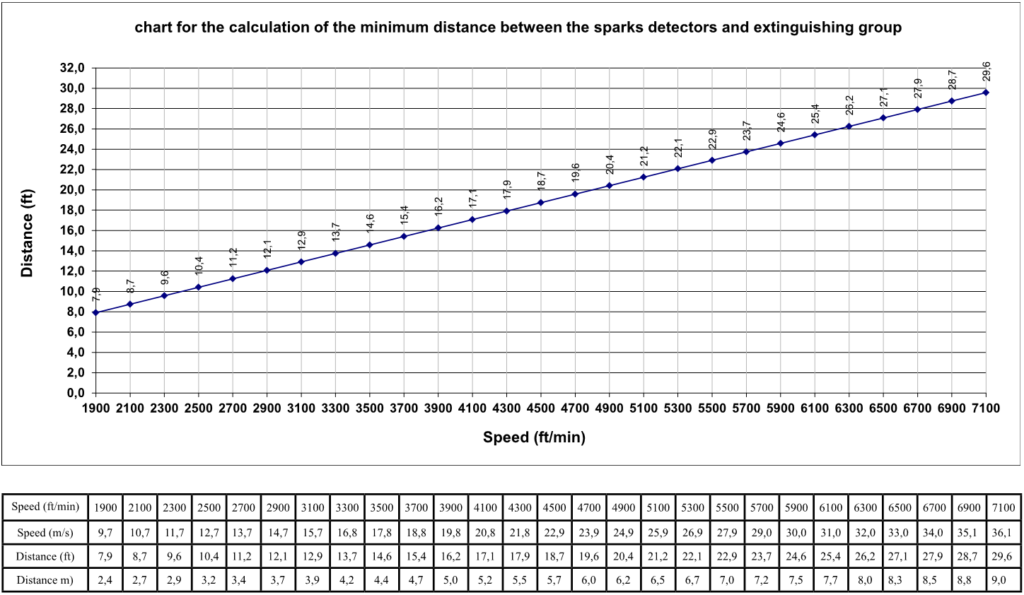

Detectors must be placed at a distance which provides enough time for the detection signal to be sent to the Fire Control Panel, the signal to be processed and sent on to the extinguishment set, and then for the extinguishment set to activate the sprinklers in the duct ahead of the spark. The time it takes to do all of this is less than 250 milliseconds, so we design the detectors to be upstream from the extinguishment set at a distance equal to or greater than 250 milliseconds of travel at the maximum designed velocity in the duct where these safety devices are installed.

Spark Detection – Extinguishment Chart (credit: Boss Products America/GM Sistemi)

HIGH SPEED ABORT GATES

When a deflagration has been detected in a dust collection system which returns the output air into the building from which it was drawn there is a risk of that fire entering the building and spreading inside. Obviously, this is extremely dangerous and must be avoided. The fire itself can cause a rapid increase in pressure within the ductwork, and an explosion by definition is an extreme change in pressure.

To reduce the risk of this event spreading within the workspace, a High Speed Abort Gate (HSAG) is used to immediately dump the output air stream into the environment and away from the building. When a spark is detected upstream from the HSAG, a heavy gauge steel diverter flap drops into the airstream and forces all returned air up through a vent atop the gate. Should there be an explosion in the ductwork, this gate will be opened before the pressure wave or flame can be returned to the building.

EcoMAXX High Speed Abort Gate, by BOSS Products America

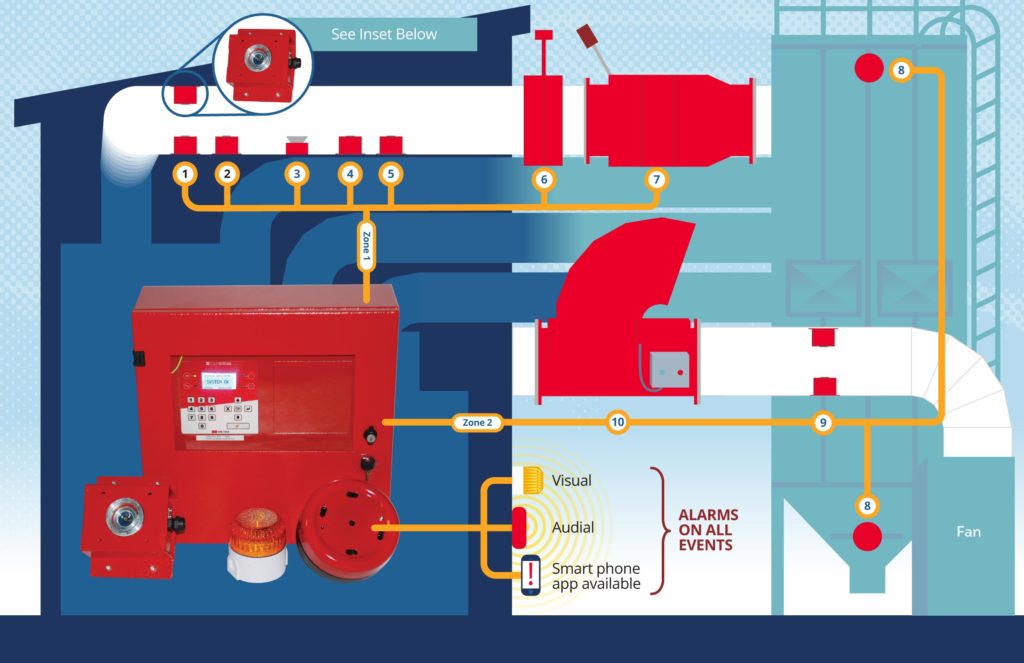

The High Speed Abort Gate can be wired in with the initial spark detectors inside the facility, or they can be wired to a detection set located on the dust collector outlet ducting downstream from the dust collection fan (see diagram at end of this article). This second arrangement allows for additional safety and control within the system, should the primary set of detection and suppression systems fail to function for whatever reason.

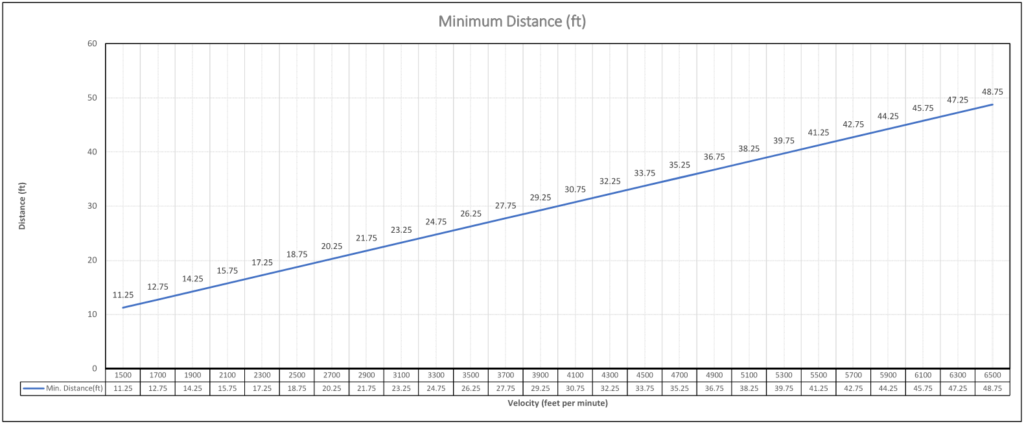

By adding a spark detection system on return air ductwork of sufficient length for detection, the HSAG can then be tripped should a spark or flame make it through the dust collector. The distance between Spark Detectors and the HSAG should be greater than the equivalent of 500 milliseconds of travel at the maximum designed velocity in the duct where these safety devices are installed.

Spark Detection – Abort Chart (credit: Boss Products America/GM Sistemi)

Contact us today for more information on selecting and designing the right fire suppression & safety equipment for your dust collection system. We sell and support Boss Products America’s EcoMAXX line of ATEX-approved safety equipment to help you meet or exceed NFPA standards for fire prevention and safety.

Complete Spark Detection and Extinguishing System (credit: Boss Products America)

- Spark Detectors

- Test Lamps

- Fire Suppression/Spark Extinguishment

- Spark Detectors

- Test Lamps

- Firebreak Shutter

- No Return Valve (NRV)

- Thermal Probe (in Dust Collector)

- Spark Detectors

- High Speed Abort Gate (HSAG)